製品説明:

API 5CTチュービングは,高品質のシームレス鋼管で,特に石油・ガス産業の要求の高いアプリケーションで使用するために設計されています.厳格なAPIスペック5CTとISO 11960規格に従って製造耐久性と強さで知られています. このパイプは,石油鉱山の様々な作業において,優れた性能,信頼性,安全性を保証します.API 5CT パイプは,石油・ガス部門における採掘・輸送プロセスにおける不可欠な部品です.

K55,N80,L80,P110等級の高級材料から作られ,API 5CTチュービングは,特定の運用要件を満たすために設計された一連の機械性能を提供しています.この材料 は 優れた 張力 力 を 備える耐腐蝕性,強度により,この管は厳しい下穴環境での使用に適しています.石油鉱山管,キャッシング管,または一般的な石油とガス管として展開されます.この製品は高圧および高温条件下で最適な性能を保証します.

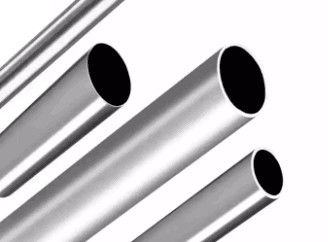

API 5CTチュービングの特徴の一つは,シームレスな構造です. 溶接管とは異なり,シームレスな鋼管は,関節なしで製造されます.構造の整合性や障害耐性を著しく向上させるこのシームレスな設計は,漏れを防止し,液体の安全な収納を確保するために不可欠であり,それによって石油フィールドの全体的な安全性と効率に貢献します.

API 5CTチュービングの表面処理は耐久性と長寿性をさらに向上させ,チュービングは,酸化,黒化,漆塗などの高度な表面処理を受けます.リン酸化 は 腐食 耐性 と 塗料 粘着 性 を 向上 さ せる 保護 層 を 提供 し ますブラック化により,環境要因や酸化への耐性が向上します.塗装 は,取り扱い や 輸送 の 間 に 磨き を 防げる 追加の 保護 層 を 追加 し て くれるこれらの処理は,管が使用期間中,その整合性と性能を維持することを共同で保証します.

API 5CTチュービングのもう一つの重要な側面は,フィールドでの接続と密封能力の容易さを決定する糸の形である.このチュービングは,丸いを含む様々な糸形で利用できます.丸い糸形は,優れた密封特性と化粧の容易さで知られており,多くの石油およびガスアプリケーションで人気のある選択となっています.バットレススレッドは,高い軸性負荷に耐えるように設計され,強力な機械的強度を提供します特殊なベーブルスレッドは,ユニークな運用要求に応じたカスタマイズされたソリューションを提供しています.これらのスレッド形式は,管の接頭間の信頼性と漏れ防止の接続を保証します.井戸の整合性を維持するために不可欠です.

API 5CTチュービングの汎用性により,石油・ガス業界では不可欠な製品となっています.井戸内の異なる地下地帯を隔離し,構造的サポートを提供するために異なるグレードと糸形との互換性により,浅井から深水掘削作業まで,幅広い用途に適応できます.

概要すると,API 5CTチュービングは,石油・ガス業界の厳しい要求を満たすために設計されたシームレス鋼管です.K55のような高品質の材料と組み合わせたN80,L80,P110は,優れた性能と信頼性を保証します.腐食や環境被害から保護するさらに,丸い,支柱,特殊なベーブルスレッドを含む複数のスレッド形式の利用性は,チュービングの適応性と接続の整合性を向上させます.油田管として使用されるかどうかAPI 5CTチュービングは,安全で効率的な井戸操作のための信頼できるソリューションです.

特徴:

- 製品名:API 5CTチュービング

- タイプ:シームレス鋼管

- 表面処理: リン化,黒化,漆塗り

- 機械タイプ: 掘削装置

- 糸のピッチオプション: 8, 10, 12, 14, 16, 18, 20 インチあたり糸

- 外径範囲: 21.9〜812.8mm

- 石油とガス管の用途に適している

- 油田管材として使用するのに最適

- 掘削管の要求のために特別に設計された

技術パラメータ:

| 機械の種類 |

掘削装置 |

| 表面処理 |

リン化,黒化,塗装 |

| 検査 |

第三者の検査,工場試験証明書,SGS,BV,DNV |

| スレッドピッチ |

8半センチあたり20本の糸 |

| 材料 |

K55,N80,L80,P110 |

| 接続 |

溶接 |

| 糸の形 |

丸い,裏付け,特殊なベーブル |

| スタンダード |

APIスペック 5CT,ISO 11960 |

| 接続タイプ |

EUE,NUE,STC,LTC,BTC |

| タイプ |

縫合のない鋼管 |

応用:

API 5CTチュービングは,高品質の中国産製品で,特に石油とガス産業で使用するために設計されています.厳格なISO 9001認証の下で製造されています.このチュービングは,厳しい掘削作業で信頼性の高い性能と耐久性を保証します.最低注文量1トンと 安全な包装と織布袋を含むパッケージの詳細により,API 5CTチュービングは安全な輸送と長期保管のために十分に準備されています.配送は40日以内に効率的に管理されます柔軟な決済条件 (LC,TTなど) が受け入れられ,さまざまな顧客のニーズに対応しています.

この管は,K55,N80,L80,P110を含む高級材料で作られ,異なる運用要件と環境条件に対応しています.異なる機械タイプとの互換性掘削プロセスにおいて不可欠な要素となります.API 5CTチュービングは,1インチあたり8〜20本のスレッドからなる複数のスレッドピッチオプションを備えています.EUEを含むいくつかの接続タイプをサポートしています.NUE,STC,LTC,BTC,様々な掘削装置に安全かつ効率的に適合することを保証します.

API 5CTチュービングは,掘削チュービングやキャッシングチュービングなどの複数のシナリオで広く使用されています.掘削管の整合性と安定性が成功した採掘プロセスに不可欠である井戸の建設で一般的に使用されています陸上または海上掘削リグで使用される場合,この管は厳しいダウンホール環境に耐え,腐食,圧力,機械的ストレスに優れた抵抗性を提供します.

API 5CTチュービングは,掘削管として主な用途に加えて,穴を埋め込み,崩壊または汚染を防ぐために不可欠なカッシングチュービングとしても使用されます.堅牢な設計と API Spec 5CT と ISO 11960 のような標準への遵守は,掘削ライフサイクルを通して安全性と効率性を維持したい油田オペレーターにとって信頼できる選択になります掘削作業の強化,井戸の整合性向上,広範囲の地質構造における自然資源の採掘を支援する.

カスタマイズ:

API 5CTチュービングの製品は,あなたの特定のニーズを満たすための包括的なカスタマイズサービスを提供します. 中国で製造されたこのシームレス鋼管は,最高品質基準に準拠しています.ISO 9001 認証及び API Spec 5CT および ISO 11960 規格の遵守を含む最低注文量は1トンで 柔軟な調達オプションを保証します

API 5CTチュービングは耐久性と性能のために設計されており,様々な掘削アプリケーションでカビチュービングとして使用するのに適しています.我々は,黒くなる耐腐食性や長寿性を高めるための塗装です

梱包は慎重に処理され,運送中に管を保護するためにバンドルや織布袋を使用します. プロジェクトを間に合うように40日以内に配達が保証されます.支払条件には LC が含まれますビジネスニーズに対応する他の柔軟な方法.

品質保証は最優先事項です. したがって,第三者の検査,工場試験証明書,SGS,BV,DNVの認証を含む徹底的な検査サービスを提供します.API 5CTチュービングカスタマイズサービスを信頼して,あなたの掘削機器の仕様に正確に調整された信頼性と高性能なキャスティングチュービングを提供してください.

サポートとサービス

API 5CTチュービングのための当社の製品技術サポートとサービスには,掘削作業における最適なパフォーマンスと信頼性を保証するための包括的な支援が含まれます.詳細な製品情報を提供します,技術データシート,および適切な処理,設置,管の保守に関するガイドライン. 私たちの専門家のチームは,材料の選択であなたをサポートするために利用できます.業界基準の遵守また,検査サービスを提供し,故障分析を行い,製品の寿命と運用安全性を向上させることができます.API 5CTチュービングアプリケーションの価値と効率を最大化するために例外的なサービスを提供することです.

梱包と輸送:

API 5CTチュービングは,製品の完全性と安全な輸送を保証するために慎重にパッケージされています.各管の関節は,しっかりと鉄筋帯で束縛され,取り扱いと輸送中に損傷を防ぐために端蓋で保護されています包装品には明瞭な製品識別ラベルが付けられており,そのラベルには,特定規格,グレード,熱番号が記載されています.

輸送のためには,移動や衝突を最小限に抑えるために適切なダッシュマテリアルを装着したパレットやコンテナにチュービングを積みます.すべての包装は国際輸送基準に準拠し,チューブが最適な状態で目的地に到着することを保証します.顧客の特定の要求を満たすために,カスタムパッケージングソリューションも要求に応じて提供されています.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!